Windlust corn mill

The beautiful historic corn mill Windlust is located in the center of Wassenaar. The windmill is a real eye-catcher and wind catcher. The tower mill, built on an octagonal base, dates from 1668 and is one of the oldest active mills in the Netherlands.

Wassenaar miller Carl Doeke Eisma has studied the history of windmill Windlust. He wrote a worthwhile book about it, "De korenmolen van Wassenaar," in which he tells the story of the mill.

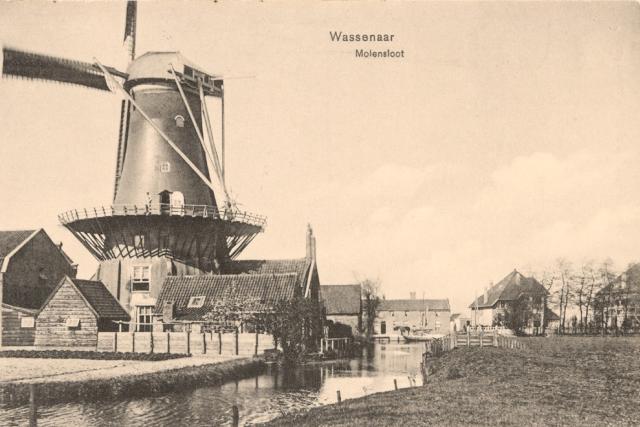

As early as 1406, records mention a corn mill in Wassenaar. This predecessor of Windlust stood at approximately the same location, according to old Maps. The mill was located outside the then village. Such a spot was strategically chosen because of optimal wind catch. Nowadays, Windlust is located in the center of the village and the mill ditch is also no longer a ditch (it was filled in at the beginning of the 20th century). But because Windlust is a tower mill, the cap towers above the buildings and the sails catch enough wind to turn and grind. The wind right also guarantees that the monument can remain in operation.

In 1668, the millers of the time received permission to build a new corn mill, which was also made in that year. In the course of time, the mill changed hands several times and, of course, the miller as well. The corn mill ground flour for both bakers and citizens of Wassenaar. On May 4, 1821, the mill was sold to Nicolaas Mansvelt. This sale ushered in a period from 1821 to 1961, during which four generations of Mansvelt worked as millers at Windlust. The mill is still popularly referred to as the "Mansvelt mill" even today. Incidentally, the name Windlust also seems to have originated in the 'Mansvelt era,' but precise information about its naming is lacking.

Many books and publications state that the mill was lost in 1861 due to lightning and fire. Further archival research by miller Eisma (including the Leijdsche Courant and the archives of the Mansvelt family) has shown that this was a misunderstanding. Yes, lightning had struck, causing destruction, but no fire had broken out.

Industrialization and associated modernization obviously had a major impact on the miller's profession and the way grain was milled. By the late 1950s, miller Mansvelt, like many other millers, had switched to a milling plant with engines at a location next to the mill. There was no longer enough money to be made from a wind-driven corn mill. Windlust had lost its function as a milling mill and still served as a residence and storage. Miller Eisma knows that in the early 1960s an interested American made an offer for the mill, for an amount of 1 million guilders. This bidder wanted to demolish the mill and rebuild it in the US. That went too far for Mansvelt; he wanted Windlust to be preserved for Wassenaar. In the end, the family sold the mill to the municipality of Wassenaar, for an amount of 20,000 guilders; a very reasonable price.

Wassenaar has owned Windlust since early 1962. For many years the mill ran, but did not grind. That didn't happen until 1983, with miller Van der Veek. Thanks to its location on the coast, the structure has endured quite a bit. Over time, the mill has been thoroughly restored many times, both interior and exterior. From floors and millstones to the cap with the sails. Originally, some parts of the mill were made of wood. These were replaced by cast iron and then steel. Sometimes restoration has caused the mill to shut down for long periods of time. The most recent restoration (2021-2022) was to address the recurring moisture problem and increase fire safety. In addition, a new color scheme was applied and the rods in the windmill's sails were also repointed; when measured through, the metal was found to be too thin.

All inhabitants of Wassenaar as well as the municipality are happy that on November 12 the monumental mill will be reopened and after more than 1.5 years of stagnation will be able to turn and grind again in all its glory.

Windlust is a tower mill. The round wind-driven corn mill stands on a high octagonal substructure with scaffolding. This octagon of about 6.5 meters is the oldest part of the construction and dates from 1668. The mill was built at the time outside the built-up area of the village of Wassenaar, next to the Molensloot. The flight of the mill (twice the sail length) is 25 meters.